Glass is amazing stuff. Understanding and taking care of it is both easy and important. To learn how and why, let’s examine the nature of glass itself.

The basic properties of glass are obvious, like clarity and color. Typically we choose from these properties when we select glass for a window, a telescope, a wine bottle, etc. Some properties aren’t so obvious, at least not to the naked eye, like it’s weight, hardness, thermal behavior, chemical sensitivity, radiation resistance and of course, cost.

The basic properties of glass are obvious, like clarity and color. Typically we choose from these properties when we select glass for a window, a telescope, a wine bottle, etc. Some properties aren’t so obvious, at least not to the naked eye, like it’s weight, hardness, thermal behavior, chemical sensitivity, radiation resistance and of course, cost.

Thinking about bottle glass; its color and clarity are important, and some minor defects (like bubbles) can be tolerated. Also important are its hardness, thermal properties, and its cost. Typically, softer glass is low cost and often less than fully transparent; it has a 'low' melting point, is easily shaped by machine, is safe for food and beverage products and can be recycled for reuse, or repurposed. In other words, it’s the perfect glass for common mass-produced general purpose bottles.

I imagine that sometime in the 1800's, someone found an empty bottle whose neck fit their finger. They picked it up and thought, "I wonder how this might sound slidin' around on my guitar?..."

They tested it and (IMHO), that's when 'cool' was born!

Fast forwarding through years of technical evolution we discover the original Pyrex-brand borosilicate ("boro") glass. This glass, made from silica with an added boron component, far exceeded the requirements for simple, mass-produced bottles. It found its way into the kitchens and laboratories of the world because it is SO HARD, just a little softer than pure quartz! It has very little sensitivity to heat change; in fact, a boro glass container under high heat can be filled with water without breaking! Boro glass is relatively clear and easily worked by hand or by machine, and it’s food and chemical safe. All of this makes it higher in cost than bottle glass.

And that's why we make guitar slides with borosilicate glass. Um, because it's hard, doncha see; real hard. When a boro slide is held against the strings of an instrument, it is affected very little by their vibration. As a result, it degrades the string’s vibration very little. The strings are free to use the slide as a fret with minimum damping, as occurs with a softer glass like a bottle neck. Because the string can resonate efficiently, it produces a sound described by some as 'rounder' or ‘fuller’ and with greater sustain than many other slide materials.

The most recent innovation in boro glass development is color. Originally available only in clear, it is now made in a rainbow of colors. The cost of color boro is somewhat higher. For our purposes, we use color boro tubing made around the world. It provides us with the widest range of colors and sizes at an affordable price. Of course, very expensive custom boro glass for slides is available, but that’s a topic for another blog. For now, let's talk about how to keep your custom-made color boro glass slide safe by applying what we know about its properties.

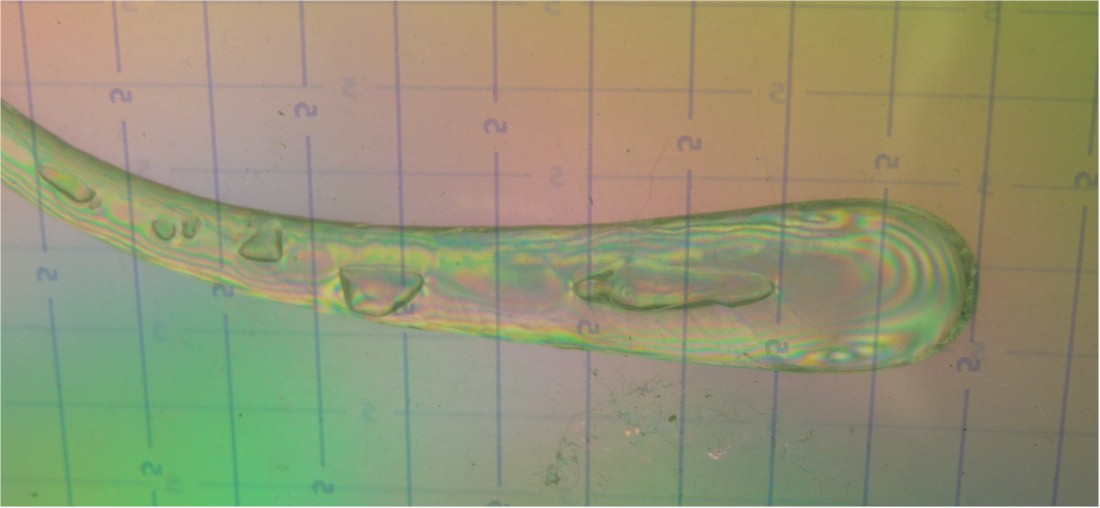

We know it's hard. It can chip or scratch softer things like mirrors, or guitars, or even other boro glass slides (you've got a couple of slides in different lengths and colors, right?). So we ship our slides in a protective burlap pouch. It's not fancy. It’s to keep the slide from harming the things around it or from being scratched. Because glass has yet another invisible property, one that comes as a result of 'working' the glass in a flame. It is internal stress. It can be seen in the photo above as 'rainbow-like' lines that swirl around in the glass droplet shown.

The more the glass is moved around (stretched, bent, blown, etc.) under a flame, the more internal stress is built up. Irregularities develop from the stress and weaken the glass invisibly making it vulnerable to either impact or scratches.

I imagine that sometime in the 1800's, someone found an empty bottle whose neck fit their finger. They picked it up and thought, "I wonder how this might sound slidin' around on my guitar?..."

They tested it and (IMHO), that's when 'cool' was born!

Fast forwarding through years of technical evolution we discover the original Pyrex-brand borosilicate ("boro") glass. This glass, made from silica with an added boron component, far exceeded the requirements for simple, mass-produced bottles. It found its way into the kitchens and laboratories of the world because it is SO HARD, just a little softer than pure quartz! It has very little sensitivity to heat change; in fact, a boro glass container under high heat can be filled with water without breaking! Boro glass is relatively clear and easily worked by hand or by machine, and it’s food and chemical safe. All of this makes it higher in cost than bottle glass.

And that's why we make guitar slides with borosilicate glass. Um, because it's hard, doncha see; real hard. When a boro slide is held against the strings of an instrument, it is affected very little by their vibration. As a result, it degrades the string’s vibration very little. The strings are free to use the slide as a fret with minimum damping, as occurs with a softer glass like a bottle neck. Because the string can resonate efficiently, it produces a sound described by some as 'rounder' or ‘fuller’ and with greater sustain than many other slide materials.

The most recent innovation in boro glass development is color. Originally available only in clear, it is now made in a rainbow of colors. The cost of color boro is somewhat higher. For our purposes, we use color boro tubing made around the world. It provides us with the widest range of colors and sizes at an affordable price. Of course, very expensive custom boro glass for slides is available, but that’s a topic for another blog. For now, let's talk about how to keep your custom-made color boro glass slide safe by applying what we know about its properties.

We know it's hard. It can chip or scratch softer things like mirrors, or guitars, or even other boro glass slides (you've got a couple of slides in different lengths and colors, right?). So we ship our slides in a protective burlap pouch. It's not fancy. It’s to keep the slide from harming the things around it or from being scratched. Because glass has yet another invisible property, one that comes as a result of 'working' the glass in a flame. It is internal stress. It can be seen in the photo above as 'rainbow-like' lines that swirl around in the glass droplet shown.

The more the glass is moved around (stretched, bent, blown, etc.) under a flame, the more internal stress is built up. Irregularities develop from the stress and weaken the glass invisibly making it vulnerable to either impact or scratches.

Here's what you need to know:

Scratches don't just look bad, they can be fatal to your slide.

Scratches don't just look bad, they can be fatal to your slide.

The science behind the destructive scratch phenomenon was first described in about 1660 by Prince Rupert of the Rhine, when he demonstrated what happens to a molten drop of glass that falls into a bucket of water. It’s amazing! When it cools down, the drop won't break, even when hit with a hammer! It's stronger than steel; BUT, if they’re scratched, they explode! If you're not familiar with “Prince Rupert's Drops,” photos can be seen at http://www.glassblower.info/prince-ruperts-drop-and-glass-stress.html, along with a slow-motion video of a drop exploding when it’s stress is released- it's awesome!

At The Rocky Butte Guitar Slide Company, extra care is taken to manage the stress we induce in our slides. While a full annealing of each slide would completely clear all stress, our efforts to manage it have shown great results. In that regard. Wikipedia states, "Especially for smaller, simpler objects, annealing may be incidental to the process of manufacture...". We strive to keep the stress we induce within the realm of suitability, and we provide a full-replacement, one-year warranty.

That's it then, keep your slide safe from scratching. By caring for it as the quality instrument accessory it is, your slide will give you many years of excellent performance. And by the way, don’t carry your slide around in your back pocket. Several people have broken their slide by sitting on it! The glass is hard, but it doesn’t like to bend.

Visit our Guitar Slides page to order one today! And Thanks for your time! Enjoy!

Custom Rocky Butte Slides: Better Because They Fit!

That's it then, keep your slide safe from scratching. By caring for it as the quality instrument accessory it is, your slide will give you many years of excellent performance. And by the way, don’t carry your slide around in your back pocket. Several people have broken their slide by sitting on it! The glass is hard, but it doesn’t like to bend.

Visit our Guitar Slides page to order one today! And Thanks for your time! Enjoy!

Custom Rocky Butte Slides: Better Because They Fit!

RSS Feed

RSS Feed